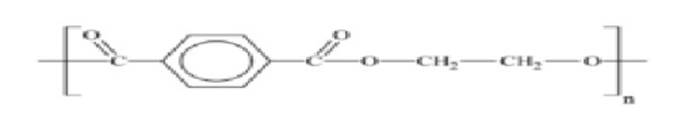

Since they were discovered in 1941, the properties of polyester polymers have become well established in the fibre, packaging and structural plastic industries, thanks to their high performance. PET is manufactured from high-specification crystallisable thermoplastic polymers. The polymer has a large number of properties suited to the production of quickly mouldable, heat-resistant high-precision components and high-quality commercial products. PET is available in transparent and coloured grades.

Advantages

Among the technical advantages of PET, mention can be made of excellent impact tolerance and stiffness. Very fast mould cycle time

and good deep-drawing characteristics with even wall thickness. No drying of plate before moulding. Wide range of use (-40° to +65°). Can be cold-formed by bending. Very good resistance to chemicals, solvents, cleaning agents, oils and fats etc. High resistance to stress cracking and crazing. PET has a number of commercial advantages. Short cycle time ensures high productivity in moulding operations. Aesthetically attractive: high gloss, high transparency or evenness of colour and can easily be printed or decorated without pre-treatment. Versatile technical performance and fully recyclable.

Uses Since it was introduced onto the market, PET has been successfully evaluated in such varied applications as sanitary ware (bathtubs, shower cubicles), the retail trade, vehicles (also caravans), telephone kiosks, bus shelters etc. PET is suitable for food and medical applications and for gamma-radiation sterilisation.

There are two main types of PET: Amorphous PET (APET) and crystalline PET (CPET), the most important difference being that CPET is partially crystallised, while APET is amorphous. Thanks to its partially crystalline structure CPET is opaque, while APET has an amorphous structure, giving it a transparent quality.

Post time: Mar-17-2020